– Gantry Type

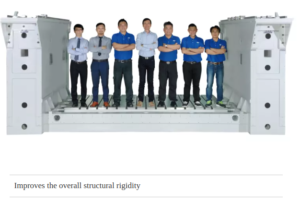

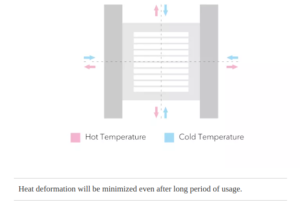

– Box in Box Symmetrical Design

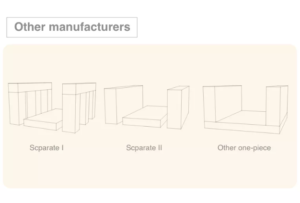

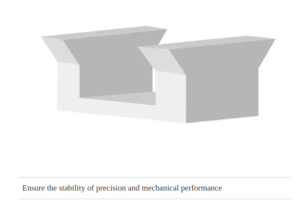

– Column and Base One-Piece Design

– X/Y-Axis Linear Motor Drive

– Feedrate: 60m/min

– Direct-Drive Motor Two-Axis Milling Head

High Rigidity Structure Design

Gantry type design, all axial components (X/Y/Z/B/C axis) is movement on the top of the column.

The work piece is fixed on the table so that the weight of the work piece does not affect the machine performance.

Column and Base One-Piece Design

Specifications

| Specifications / Mold | Unit | Compact B-2516 | Compact B-2522 | Compact B-3222 |

| X-axis Travel | mm | 1600 | 2200 | 2200 |

| Y-axis Travel | mm | 2500 | 2500 | 3200 |

| Z-axis Travel | mm | 1250 | 1250 | 1250 |

| Table | ||||

| Table size | mm | 2500x1600 | 2500x2200 | 3200x2200 |

| T-slot size (width) | mm | 22 | 22 | 22 |

| Table load | Kg/m2 | 4000 | 4000 | 4000 |

| Distance between spindle nose | mm | 250-1500 | 250-1500 | 250-1500 |

| Distance between column | mm | 3225 | 3225 | 3925 |

| Feedrare | ||||

| X/Y/Z-axis drive mode | X/Y/Z | Linear motor/ Linear motor / Dual ball screws | ||

| X/Y/Z-axis rapid feedrate | m/min | 60/60/50 | 60/60/50 | 60/60/50 |

| Auto tool changer | ||||

| Tool shank | HSK A63 | HSK A63 | HSK A100 | |

| Tool magazine capacity | Pcs | 30 | 30 | 30 |

| Max. tool weight | Kgs | 8 | 8 | 15 |

| Max. tool length | mm | 350 | 350 | 350 |

| Max. tool diameter | mm | Ø 75 | Ø 75 | Ø 125 |

The Company reserves the right to change, with all the technical specifications of the contract-based technology.

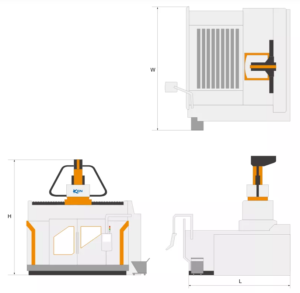

| Compact B-2516 | Compact B-2522 | Compact B-3222 | |

| L(Length) | 5300 | 5900 | 6120 |

| W(Width) | 6139 | 6139 | 6838 |

| H(High) | 5980 | 5980 | 5980 |

Accessories

Standard

- Heidenhain TNC-640 controllers. (X, Y, Z, A, C-five-axis Continuous)

- Heidenhain Handwheel –HR520.

- Europe 2-axis milling head TCH-19 (A63).

- European system of vertical spindle HSK A-63 24,000 RPM

- HSK A-63 30 tools magazine.

- X /Y axis Linear motor coolant system.

- 12 roller linear guideways (4 sets for X / Y / Z axis)

- 4 Heidenhain linear scale (2 sets for X-axis, 2 sets for Y / Z axis)

- The spindle and milling head coolant system.

- Spindle oil mist lubrication system.

- Cutting oil mist device.

- Front-type chip conveyor containing iron filings cars each 1 style.

- Front and rear working door safety interlock. (each type)

- Waterproof work light.

- Used in all meta international system of units (si) standards.

- Protection devices complete and reliable, work area safety, according to ISO 12100-1 & -2 1992.

- Electrical cabinet with air-conditioning system, filtration and ventilation installations and variety of electrical protection.

- Machine standard color.

Option

- THC-19 (A100) Modular 2-axis Milling Head + 15,000 RPM spindle.

- ATC System Magazine Capacity (option).

- (HSK-A100)-60 tools / (HSK-A63)-60 tools.

- Siemens-840D CNC controllers.

- Laser tool measuring system.

- Touch probe for work piece measuring.

- Coolant through spindle 20/30/40 bar.

- Transformer.

- Voltage stabilizer.

- Spiral-type chip conveyor on both side of worktable area.

- GPS(Global Pgm Setting) Hand wheel function.

- Blum form control comparison software.

- Automatic Kinematics 5-axis compensation function.

- Enclosed rooftop.

- Oil mist recovery system.