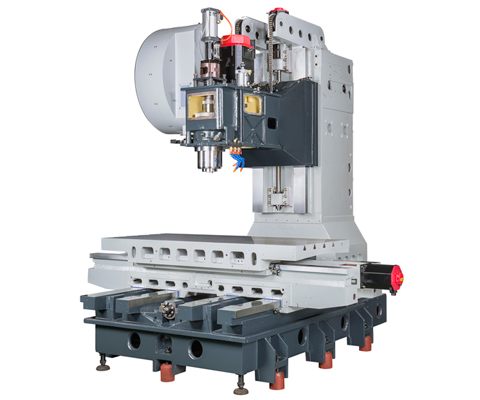

Outstanding Features:

- X,Y,Z axes are rigid box type slidewyas, All slideways are hardened and precision ground and then coated with high quality, low friction Turcite-B for maximum wear resistance. The mating surfaces are precision treated for long term accuracy.

- Optimized machine construction. The major machine parts, such as base, column and saddle, etc., are manufactured from high quality alloy cast iron. It features maximum material stability, minimum deformation and lifetime accuracy. Square slideways standards.

Specification

| Model | VMC-1690 | |

|---|---|---|

| TRAVEL | X x Y x Z axis | 1,600 x 900 x 700 mm |

| Spindle nose to table | 200~900 mm | |

| Spindle center to solid column surface | 990 mm | |

| TABLE | Working area | 1,900 x 850 mm |

| Max. loading | 2,000 kg | |

| T-Slots (No. x Width x Pitch) | 5 x 22 mm x 150 mm | |

| SPINDLE | Tool shank | BT-50 |

| Speed | 6,000 rpm | |

| Transmission | 2-Speed Geared Head | |

| Bearing lubrication | Grease | |

| Cooling system | Oil cooled | |

| Spindle motor max.rating (MITSUBISHI) | 15 kw (20HP) | |

| Spindle motor max.rating (FANUC) | 18.5 kw (25HP) | |

| Axis motor max.rating (MITSUBISHI) | 3.5 / 4.5 / 3.5 kw | |

| Axis motor max.rating (FANUC) | 3.0 / 3.0 / 3.0 kw (STD) 7.0 / 7.0 / 7.0 kw (OPT) |

|

| FEED RATES | Rapids on X & Y & Z axes | 15 / 15 / 15 m/min |

| Max. cutting federat | 12 m/min | |

| TOOL MAGAZINE | Tool storage capacity | 24 arm (32 arm opt.) |

| Type of tool (optional) | BT- 50 (CAT- 50) | |

| Max. tool diameter | 110 mm | |

| Max. tool weight | 15 kg | |

| Max. tool length | 300 mm | |

| AVG.CHANGING TIME (ARM) |

Tool to tool | 3.8 sec. |

| Chip to chip (50% Z axis) | 11 sec. | |

| Air source required | 6 kg / cm2 up | |

| ACCURACY | Positioning | P 0.01 mm |

| Repeatability | Ps 0.006 mm | |

| DIMENSION | Machine weight (Net) | 14,800 kg |

| Power source required (KVA.) | 35 | |

| Floor space (L x W x H) | 4,030 x 3,675 x 3,280 mm | |

| Shipment advice | 1 x 20'FR (1 set) |

Standard Accessories

- Mitsubishi M80 controller

- Spindle speed 6,000 (Gear)

- Automatic tool changer

- YZ-axis slant cover protection chip auger (work table rear)

- Full splash guard

- Heat exchanger for electric cabinet

- Automatic lubricating system

- Spindle oil cooler

- Spindle air blast system (M code)

- Spindle air blow system

- Spindle orientation

- Coolant gun and air socket

- Leveling kits

- Removable manual & pulse generator (M.P.G.)

- LED light

- Rigid tapping

- Coolant system and tank

- Cycle finish indicator and alarm lights

- RS-232C interface with cable (10 m)

- Tool Box

- Operational and maintenance manual

- Transformer

- Spindle coolant ring(M code)

- Chip flush

Optional Accessories

- Spindle speed 10,000 rpm (Direct type)

- Coolant through spindle (CTS)

- Automatic tool length measuring device

- Automatic work piece measurement system

- CNC rotary table and tailstock

- Oil skimmer

- Link type chip conveyor with chip bucket

- Linear scales (X/Y/Z axis)

- Coolant through tool holder